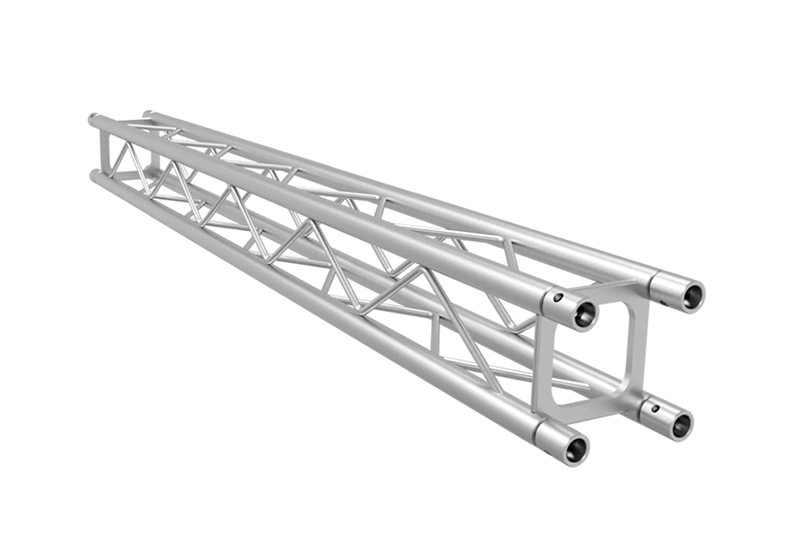

Шензен Чангjianшун Science and Technology Co., Ltd, стратегически разположена в Шензен, пionерният град на реформите и отварянето на Китай, се специализира в производството и продажбата на кръчки за сценични лампи и метални изделия. Фирмата, оснащена с посветена екипажа за РИиД и продажби, разполага с персонал от над 100 души и функционира в модерно здание с площ 3000 квадратни метра, включително независима лаборатория за тестове. Получили сме сертификацията на качествената система IS09001 през 2011 г. и TUV сертификация за безопасност на нашите кръчки за сценични лампи от Рейн, Германия, и оставаме непоколебими в нашето стремеж да предоставяме най-безопасните и най-надеждни продукти на всеки потребител.

С богат история от 12 години в областта на леките хуки и конструкции, гордеем се, че предлагаме продукти от първа класа, подкрепени от отличен сервиз и професионална технология. Нашата продукция разполага с широка адаптивност, отговаряйки на различни среди и ситуации. Изработени от висококачествени метални материали, нашите продукти разполагат с изключителна корозионна устойчивост, устойчивост към износ и продължителен срок на служба.

BG

BG

EN

EN AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

MK

MK

EU

EU

KA

KA