Shenzhen Changjianshun Science and Technology Co., Ltd., strategicky umístěná v městě Shenzhen, předním městě čínské reformy a otevřenosti, se specializuje na výrobu a prodej háčků pro scénické lampy a kovového hardware. Naše společnost, vybavená věnovaným týmem pro vývoj a prodej, má více než 100 zaměstnanců a působí v moderní budově o rozloze 3000 čtverečních metrů, která zahrnuje nezávislé testovací laboratoře. Dosáhli jsme certifikace kvalitního systému IS09001 v roce 2011 a certifikace bezpečnosti TUV pro naše scénické lampové háčky od Renu v Německu, a zůstáváme neochvějně oddaní poskytování nejbezpečnějších a nejspolehlivějších produktů každému uživateli.

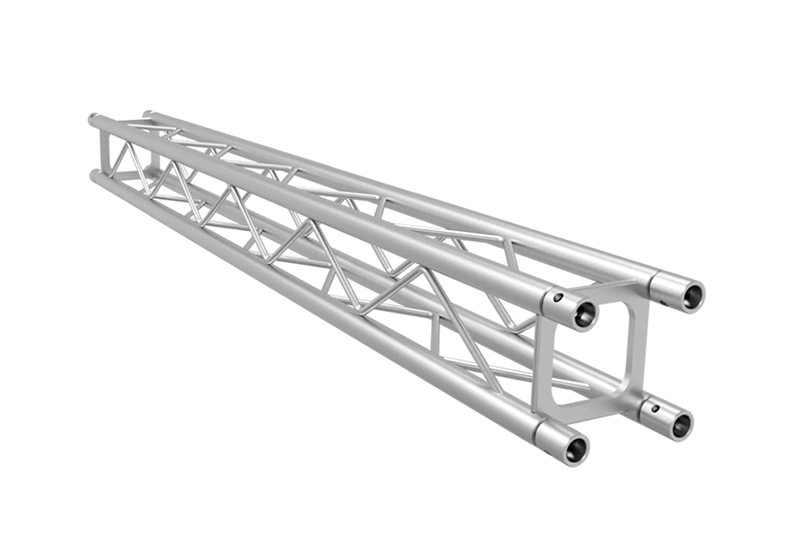

S bohatou historií 12 let v oboru lehkých háčků a nosných konstrukcí se pyšníme dodávkou produktů první třídy, podporovaných vynikajícím servisem a profesionální technologií. Naše produkty nabízejí širokou přizpůsobitelnost, vyhovující různorodým prostředím a příležitostem. Vyrobené z kvalitních kovových materiálů mají naše produkty vynikající odolnost proti korozii, méně se opotřebovávají a disponují dlouhou životností.

CS

CS

EN

EN AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

MK

MK

EU

EU

KA

KA