Shenzhen Changjianshun Science and Technology Co., Ltd, estratégicamente ubicada en Shenzhen, la ciudad de vanguardia de la reforma y apertura de China, se especializa en la producción y venta de ganchos y hardware de lámparas de escenario. Nuestra empresa, equipada con un equipo dedicado de I+D y ventas, cuenta con una fuerza laboral de más de 100 empleados y opera desde una moderna instalación de 3000 metros cuadrados, que incluye un laboratorio de pruebas independiente. Habiendo obtenido la certificación del sistema de calidad IS09001 en 2011 y la certificación de seguridad TUV para nuestros ganchos de lámparas de escenario de Rin, Alemania, no damos marcha atrás en nuestro compromiso de proporcionar los productos más seguros y confiables a cada usuario.

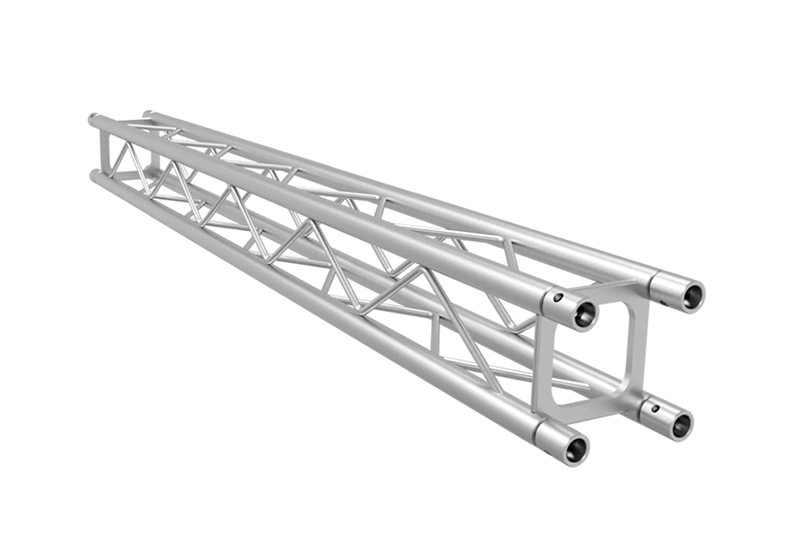

Con una rica historia de 12 años en el campo de los ganchos y grúas de luz, nos enorgullecemos de ofrecer productos de primera calidad, respaldados por un excelente servicio y tecnología profesional. Nuestra línea de productos exhibe una amplia adaptabilidad, atendiendo a diversos entornos y ocasiones. Fabricados con materiales metálicos de alta calidad, nuestros productos cuentan con una resistencia excepcional a la corrosión, al desgaste y a una vida útil prolongada.

ES

ES

EN

EN AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

MK

MK

EU

EU

KA

KA