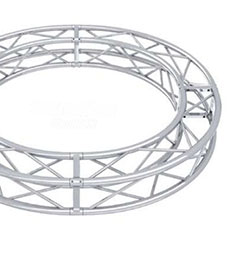

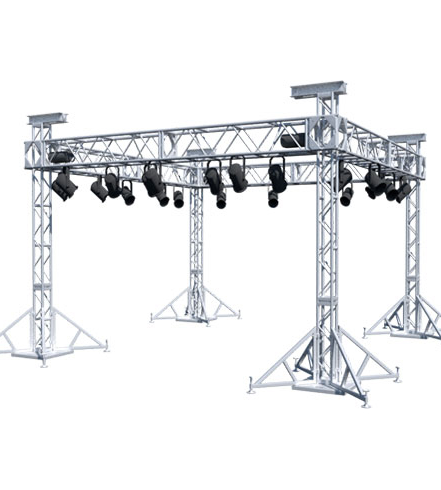

Სპიგოტი ტრასი იხსნება როგორც სტრუქტურული კანვა, რაც საშუალებას აძლევს ღონისძიების დიზაინერებს გაათავისუფლონ თავიანთი შემოქმედება შეუზღუდავი თავისუფლებით. Ტრასის მოდულური მრავალფეროვნება თამაშის შეცვლილია, რომელიც სთავაზობს მრავალფეროვან კონფიგურაციებს, რომლებიც ადაპტირდება თითოეული ღონისძიების უნიკალურ მოთხოვნებზე. Რთული განათების მოწყობილობებიდან, რომლებიც ცეკვავენ შემოქმედებითობას, ფართო სცენის დიზაინებამდე, რომლებიც იზიდავენ აუდიტორიას, სპიგოტი ტრასი ხდება წარმოსახვის გამოხატვის გამნაწილებელი. Მისი ადაპტირებადობა გადის ფუნქციონალზე, უზრუნველყოფს შეუფერხებელ ინტეგრაციას მრავალფეროვან ღონისძიების წარმოებებში, მიუხედავად იმისა, თუ რა შემოქმედებითი ხედვაა მოქმედებაში. Ღონისძიების დიზაინერებს ახლა აქვთ ინსტრუმენტი, რომელიც არა მხოლოდ აკმაყოფილებს, არამედ აღემატება მათ მოლოდინებს, რომელიც არამხოლოდ სტრუქტურებს, არამედ გამოცდილებებსაც აწვდავს.

Ბრენდი Spigot Truss მნიშვნელოვნად შეცვალა ჩვენი აღქმა სტრუქტურული აწყობის შესახებ ღონისძიებების წარმოების დინამიურ სამყაროში. ეს არის ჭკვიანი კავშირების სისტემა, რომელიც აღემატება ნებისმიერ სხვა სპიგოტ ტრასს. არ არის გასაკვირი, რომ ისინი ახლა მთავარი მომწოდებლები არიან ტრასებისთვის, რომლებიც ინტუიციურად გაწვდილი შეერთების მექანიზმით არის გაწვდილი. ახლა გეგმავლებმა კიდევ ერთი მნიშვნელოვანი ინსტრუმენტი მიიღეს, რომელიც აჩქარებს მშენებლობას და უზრუნველყოფს მყარ ფუნდამენტის ჩაყრას. ასეთი უჩვეულო ეფექტურობა არამხოლოდ ამარტივებს დავალებას; ის Spigot Truss-ს ხდის ერთ-ერთ ყველაზე საოცარ ცვლილებად ღონისძიებების ინფრასტრუქტურაში, როგორიცაა ის, რაც ცხოვრებაში არსებული ქსოვილის მსგავსია, სხვა რამეებს შორის.

Სპიგოტ ტრასის წარმოება არა მხოლოდ ინჟინერიის შედევრია, არამედ ის ასევე წარმოადგენს გარემოსდაცვითი preocupations პრაქტიკაში. მდგრადი პრაქტიკები გამოიყენება წარმოების პროცესში, რომელიც იწყება მასალების ყურადღებით შერჩევით და გრძელდება ეკოლოგიურად მეგობრული წარმოების ტექნიკებით. მწარმოებლები უნდა დარწმუნდნენ, რომ მათი პროდუქტი მინიმალურ ეკოლოგიურ ზემოქმედებას ახდენს. სპიგოტ ტრასი მაშინ ხდება მეტი, ვიდრე უბრალოდ ტრასირების სისტემა; ეს არის ჩვენი ვალდებულება მდგრადობის მიმართ, რომელზეც ვერ ვიქნებით კომპრომისული. როდესაც ღონისძიების ორგანიზატორები არჩევენ სპიგოტ ტრასს, ისინი მყარად პოზიციონირებენ ინოვაციის და გარემოს პასუხისმგებლობის დისკურსში, thereby ensuring that today’s events give way for a greener and sustainable tomorrow.

Როგორც კატალიზატორი სწრაფი დაწყებისა და მუდმივი შთაბეჭდილებებისათვის ღონისძიების წარმოების დინამიურ ეკოსისტემაში, სუპოტის ბოძები შეუცვლელია. უმაღლესი სიჩქარე ეს სრულყოფილი ბალანსი Spigot Truss- ს აძლევს მსუბუქ დიზაინს მარტივი მოხმარებისთვის და ამავე დროს უზრუნველყოფს ხანგრძლივ გამძლეობას, რომელიც გაუძლებს მძიმე გამოყენებას. ამგვარად, ეს გადაწყვეტილება არა მხოლოდ უშუალო მოთხოვნებს აკმაყოფილებს, არამედ ასევე ხატავს თავის სახელს საიმედოობისა და ხანგრძლივობის სვეტებზე.

Spigot Truss არის არა მხოლოდ სტრუქტურული გადაწყვეტა ღონისძიებების პროფესიონალებისთვის, რომლებიც ინდუსტრიის ფართო გზებზე ნავიგირებენ; ის გარდაიქმნება íntimate მეგობრად ტურზე. ის ისეა შექმნილი, რომ მსუბუქია და ამავე დროს დიდხანს გაძლებს. ეს Spigot truss-ს იდეალურ ხდის ტრანსპორტირების სირთულეების და ადგილზე მართვის საკითხების მოგვარებისთვის ტურის წარმოების დროს. მონტაჟისა და დემონტაჟის ეფექტურობა შეიძლება განვითარდეს როგორც სტრატეგიული უპირატესობა, რაც ტურების მოწყობას დაეხმარება მჭიდრო გრაფიკების მართვაში მარტივად. ტურის მეგობრის რანგში, Spigot Truss გაწვდავს წინასწარ წარმოდგენას იმაზე, რაც სავარაუდოდ მოხდება ტურზე, რადგან ის არა მხოლოდ აკმაყოფილებს, არამედ წინასწარ ელის მუდმივად ცვალებად ტურების გარემოს გარკვეულ მოთხოვნებს. მისი ეფექტურობა ამ პროდუქტს ძალიან საჭიროებს იმათთვის, ვინც ეძებს სანდო და ეფექტურ trusses გადაწყვეტებს, რადგან როდესაც لديك Spigot Truss, დარწმუნებული ხართ, რომ თქვენი მიზნების მიღწევა მარტივად შეგიძლიათ.

Shenzhen Changjianshun მეცნიერება და ტექნოლოგია Co., Ltd, სტრატეგიულად მდებარეობს Shenzhen, წინა ქალაქში ჩინეთის რეფორმისა და გახსნის, სპეციალიზებულია წარმოების და გაყიდვების სცენაზე ნათურა hooks და აპარატურა. ჩვენი კომპანია, რომელიც აღჭურვილია სპეციალური კვლევებისა და განვითარებისა და გაყიდვების გუნდით, ამაყობს 100-ზე მეტი თანამშრომლით და მუშაობს თანამედროვე 3000 კვადრატული მეტრის ფართობზე, რომელიც მოიცავს დამოუკიდებელ ტესტირების ლაბორატორიას. 2011 წელს ISO9001 ხარისხის სისტემის სერტიფიცირების მიღწევის შემდეგ და TUV უსაფრთხოების სერტიფიცირება ჩვენი სცენის ნათურების თოჯინებისთვის რაინიდან, გერმანია, ჩვენ ვართ ურყევი ჩვენს ვალდებულებაში, უზრუნველვყოთ ყველაზე უსაფრთხო და საიმედო პროდუქტები თითოეულ მომხმარებელს

12 წლიანი გამოცდილებით სინათლის ხრახნებისა და ხრახნების სფეროში, ჩვენ ვამაყობთ პირველი კლასის ხარისხის პროდუქციის მიწოდებით, რომელიც მხარდაჭერილია შესანიშნავი მომსახურებით და პროფესიონალური ტექნოლოგიით. ნაპართა ლანჟა თევზს თევზს აჟღეანთ ფართო ადაპტაბილურობა, რწ ვთევზთ ნაჟვრაჟნ ჟრანდთრვ თ ჟრანდთრვ. ჩვენი პროდუქცია დამზადებულია უმაღლესი ხარისხის ლითონის მასალებით.

Გამოცდილებით მიიღეთ სრულყოფილი მორგების მომსახურების სიმარტივე, რომელიც უზრუნველყოფს ერთჯერად გადაწყვეტას ყველა თქვენი მოთხოვნისთვის. ჩვენი ვალდებულება არის კონცეფციიდან მიწოდებამდე მორგებული გამოცდილების მიწოდება, რაც უზრუნველყოფს თქვენი უნიკალური საჭიროებების შეუფერხებელ დაკმაყოფილებას.

Ეა ჟთ ოჲბპვეა ჟჲ ნაჟ ნაჟ ნაჟჲბვნჲჟრ ჱა ოჲეჲბპვჟრ. 2011 წლიდან IS09001 ხარისხის სისტემის სერტიფიცირებით და TUV უსაფრთხოების სერტიფიცირებით ჩვენი სცენის ნათურების ხრახნებისთვის რაინიდან, გერმანია, ჩვენ პრიორიტეტი გვაქვს პროდუქციის მიწოდება, რომელიც აღემატება უსაფრთხოების უმაღლეს სტანდარტებს, რაც

Სარგებლობა ჩვენი ვრცელი 12 წლის გამოცდილება სინათლის hooks და trusses. ჩვენ ვამაყობთ უმაღლესი ხარისხის, შესანიშნავი მომსახურებისა და პროფესიონალური ტექნოლოგიების მიწოდებით. ეს ვალდებულება ასახავს ჩვენს ღრმა ინდუსტრიის ცოდნას და წლების ღირებულ გამოცდილებას.

Ჩვენი მსუბუქი ხრახნებისა და ხრახნების პროდუქტები გამოირჩევა მრავალმხრივი ადაპტაციით, სხვადასხვა გარემოში და შემთხვევებში სხვადასხვა მოთხოვნების დაკმაყოფილებით. გამოცდილებით ჩვენი შეთავაზებების მოქნილობა, შეუფერხებლად ინტეგრირება სხვადასხვა პარამეტრ

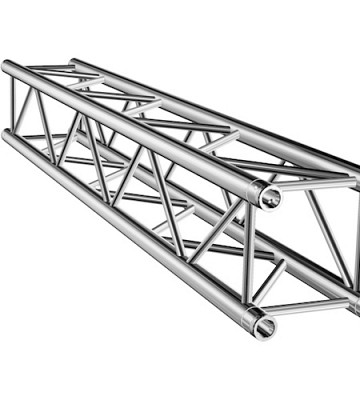

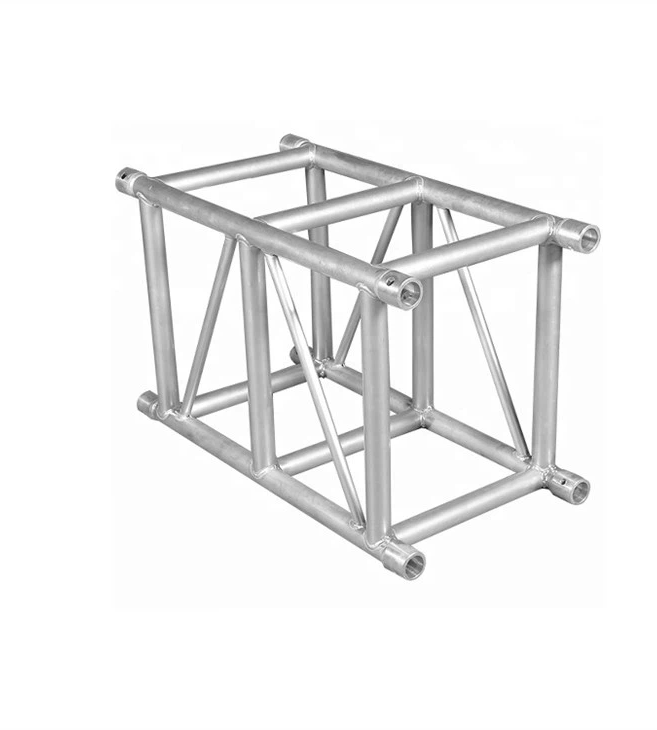

Სპიგოტ ტრასი გამოირჩევა სტრუქტურული სტაბილურობით მისი ზუსტი კონუსური პინების კავშირების გამო. Ეს უზრუნველყოფს მყარ და უსაფრთხო ჩარჩოს, რაც მნიშვნელოვანია მძიმე ტვირთების და ფართო ღონისძიებების მოწყობის მხარდაჭერისთვის.

Სპიგოტის ტრასის მოდულური დიზაინი საშუალებას აძლევს შემოქმედებით კონფიგურაციებს, რაც დიზაინერებს საშუალებას აძლევს სტრუქტურები მოარგონ უნიკალურ ღონისძიების მოთხოვნებს. Ეს მრავალფეროვნება უზრუნველყოფს, რომ ტრასის სისტემა შეუფერხებლად შეესაბამება სხვადასხვა შემოქმედებით ხედვებს.

Სპიგოტის ტრასი აღწევს ჰარმონიულ ბალანსს, კომბინირებით მდგრად მასალებს მსუბუქ დიზაინთან. Ეს არა მხოლოდ უზრუნველყოფს სტრუქტურული მთლიანობის შენარჩუნებას, არამედ ამარტივებს ტრანსპორტირებას და ადგილზე მართვას, რაც პასუხობს პრაქტიკულ პრობლემებს ღონისძიების პროფესიონალებისთვის.

Სპიგოტის ტრასი გამოირჩევა უნიკალური შეერთების სისტემით, რომელიც აქვს გაწვდილი პინი, რაც საშუალებას აძლევს სწრაფ და უსაფრთხო აწყობას. Მისი ეფექტური დიზაინი მინიმუმამდე ამცირებს მონტაჟის დროს, რაც კრიტიკულად მნიშვნელოვანია დროის მიმართ მგრძნობიარე ღონისძიებებისთვის.