Selain daripada kekuatan strukturnya, yang sistem kekuda menjadi kanvas untuk ekspresi estetik. Dengan reka bentuk yang anggun dan boleh disesuaikan, ia menyatu dengan bahasa visual pelbagai produksi pentas. Alkimia estetik ini mengubah sistem truss dari sekadar keperluan struktur kepada elemen reka bentuk yang meningkatkan daya tarikan keseluruhan pentas. Ketika elemen pencahayaan dan pemandangan menari dengan anggun dari sistem truss di atas, ia menjadi bahagian penting dalam penceritaan visual, menambah kedalaman dan dimensi kepada naratif artistik.

Cara yang paling berkesan untuk melakukan perkara dalam dunia pengurusan acara yang sentiasa berubah adalah kecekapan. Kami telah memudahkan proses untuk menyusun sistem truss yang lancar, menjadikan pemasangan satu urusan yang kurang kompleks. Ini menjadi mungkin dengan menggabungkan reka bentuk mesra pengguna dan ciri intuitif di antara elemen lain yang sepatutnya menjadikan persediaan satu proses yang lancar, mengurangkan masa henti semasa persiapan pengeluaran. Sebenarnya, ia melangkaui kemudahan memandangkan ia adalah kelebihan strategik yang memberikan ruang untuk mengoptimumkan aktiviti perancang acara dan anggota kru. Apabila anda memilih sistem truss kami, anda memilih pendekatan yang tidak rumit untuk memasang satu yang akan meningkatkan produktiviti sambil meminimumkan gangguan agar dapat mengekalkan fokus pada aspek kreatif dan artistik pengeluaran.

Salah satu perkara luar biasa tentang dunia pengeluaran acara adalah bahawa sistem truss kami memerlukan keteguhan, bersedia untuk menghadapi sebarang cabaran persekitaran. Sistem ini diperbuat daripada bahan yang boleh menahan keadaan cuaca yang keras dan sesuai untuk digunakan di dalam dan luar ruangan. Sistem truss kami adalah kuat oleh itu ia berfungsi secara konsisten sama ada terdedah di bawah langit terbuka atau terkurung dalam persekitaran terkawal di lokasi dalam. Kebolehsuaian kepada pelbagai keadaan persekitaran menjadikannya cukup serba boleh untuk menjadi jawapan yang boleh dipercayai bagi penganjur yang merancang acara di setiap lokasi tanpa mengira cabaran elemen alam.

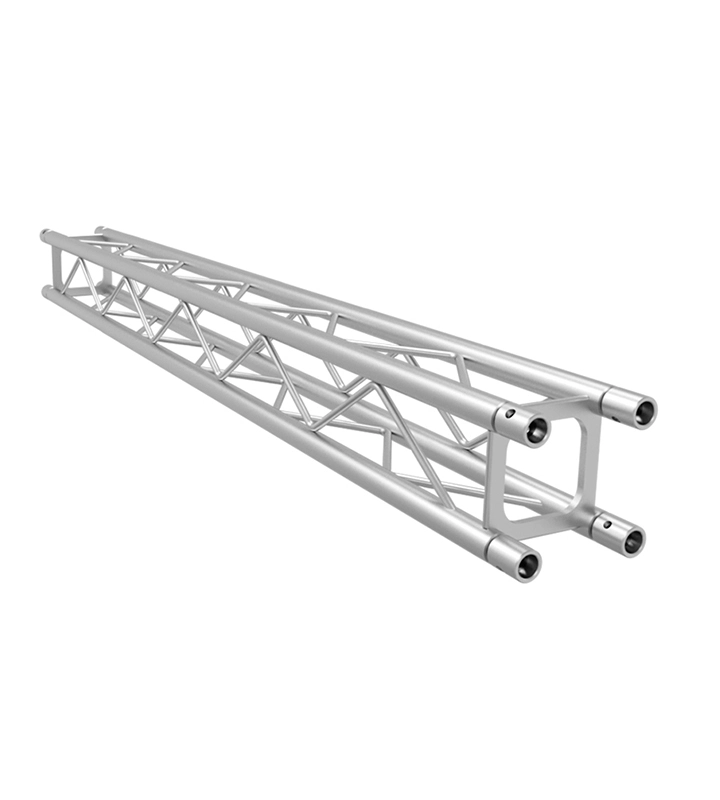

Selain daripada kepakaran strukturnya, sistem truss kami mewakili kualiti estetik. Ia dibuat dengan reka bentuk yang licin dan boleh disesuaikan, yang menjadikannya selari dengan bahasa visual mana-mana produksi pentas. Perubahan penting ini mengubah sistem truss daripada sekadar keperluan struktur kepada satu yang meningkatkan daya tarikan pemandangan di pentas. Saat pencahayaan dan elemen pemandangan meluncur dengan lembut melalui sistem truss di atas, ia menjadi sebahagian daripada penceritaan visual dan menambah satu lapisan lagi untuk meningkatkan naratif artistik. Ia menggabungkan bentuk dengan fungsi dalam satu penggabungan seni dan kejuruteraan yang menghasilkan satu pemandangan yang menarik untuk mata.

Dunia perancangan acara tidak pernah statik dan sistem truss kami, sebagai agen perubahan, mengubah fabrik pengalaman langsung. Ia bukan penyelesaian biasa; ia adalah perkembangan teknologi yang maju, sebuah karya kejuruteraan yang direka dengan baik dan sebuah karya seni yang halus dari segi ketepatan. Juga, sistem truss kami melangkaui asas dalam pengikatan pentas untuk mencipta ruang bagi acara yang lebih daripada yang dilihat. Bertindak sebagai simbol inovasi yang mendorong acara ke tahap yang lain, ia menyediakan asas yang kukuh untuk menggabungkan pencahayaan, bunyi, elemen pemandangan dengan sempurna sambil juga meningkatkan kreativiti artistik dan kepakaran teknikal dalam produksi.

Shenzhen Changjianshun Science and Technology Co., Ltd, secara strategis terletak di Shenzhen, kota pelopor reformasi dan pembukaan China, khusus bergerak dalam produksi dan penjualan kait lampu pentas serta peralatan keras. Perusahaan kami, dilengkapi dengan tim R&D dan penjualan yang khusus, memiliki lebih dari 100 karyawan dan beroperasi dari fasilitas modern seluas 3000 meter persegi, yang mencakup laboratorium uji mandiri. Setelah memperoleh sertifikasi sistem kualitas IS09001 pada tahun 2011 dan sertifikasi keselamatan TUV untuk kait lampu pentas kami dari Rhine, Jerman, kami tetap teguh pada komitmen kami untuk menyediakan produk yang paling aman dan dapat diandalkan kepada setiap pengguna.

Dengan sejarah kaya selama 12 tahun dalam bidang kait dan rangka penyangga ringan, kami bangga menawarkan produk dengan kualitas kelas satu, didukung oleh pelayanan istimewa dan teknologi profesional. Barisan produk kami menunjukkan adaptabilitas yang luas, memenuhi berbagai lingkungan dan acara. Dibuat dari bahan logam berkualitas tinggi, produk-produk kami memiliki ketahanan korosi yang luar biasa, ketahanan aus, dan masa pakai yang panjang.

Pengalaman kemudahan perkhidmatan penyesuaian komprehensif yang menyediakan penyelesaian sehenti untuk semua keperluan anda. Komitmen kami adalah untuk menyampaikan pengalaman yang disesuaikan dari konsep hingga penghantaran, memastikan kepuasan yang lancar terhadap keperluan unik anda.

Pastikan komitmen kami yang kukuh untuk keselamatan. Dengan pensijilan sistem kualiti IS09001 sejak 2011 dan pensijilan keselamatan TUV untuk kait lampu pentas kami dari Rhine, Jerman, kami memberi keutamaan untuk menyampaikan produk yang melebihi standard keselamatan tertinggi, memastikan kebolehpercayaan untuk setiap pengguna.

Manfaat daripada pengalaman kami yang luas 12 tahun dalam kait cahaya dan truss. Kami berbangga dalam menyampaikan kualiti terbaik, perkhidmatan yang sangat baik, dan teknologi profesional. Komitmen ini mencerminkan pengetahuan industri kami yang mendalam dan pengalaman berharga bertahun-tahun.

Produk cangkuk ringan dan truss kami mempunyai fleksibiliti serba boleh, menangani pelbagai keperluan dalam pelbagai persekitaran dan majlis. Rasai fleksibiliti tawaran kami, bersepadu dengan selongsong ke dalam pelbagai tetapan untuk menyediakan penyelesaian yang disesuaikan untuk setiap aplikasi.

Sistem truss kami mempunyai reka bentuk yang kukuh, memastikan kestabilan untuk pemasangan pencahayaan dan bunyi yang luas yang biasa dalam konsert besar.

Ya, sistem truss kami menjalani ujian yang ketat untuk memastikan ia dapat menyokong beban yang besar dengan selamat, mengutamakan keselamatan peralatan yang digantung.

Ya, sistem truss kami direka dengan bahan tahan cuaca, menjadikannya sesuai untuk acara dalaman dan luaran, memastikan ketahanan dalam pelbagai keadaan persekitaran.

Sistem truss kami mempunyai reka bentuk mesra pengguna, memudahkan proses pemasangan, mempercepatkan penyediaan, dan meminimumkan masa henti semasa persiapan pengeluaran.