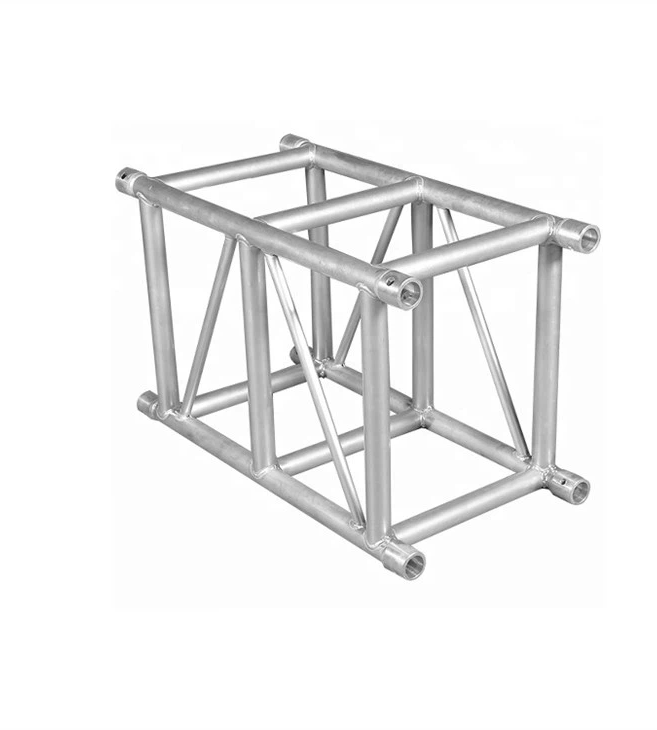

Kręgosłup sukcesu trussu spigot leży w jego niezrównanej stabilności strukturalnej, dzięki genialnej zalecie stożkowego bolca. Ta cecha zapewnia bezpieczną i stabilną konstrukcję zdolną do pewnego wsparcia różnorodnych struktur eventowych. Niezależnie od tego, czy dźwiga ciężar oświetlenia, skomplikowanego sprzętu audio, czy wyszukanych projektów scenicznych, truss spigot doskonale utrzymuje integralność strukturalną w najbardziej wymagających warunkach. Organizatorzy wydarzeń i profesjonaliści zajmujący się riggingiem powierzają swoje ustawienia trussowi spigot, uznając go nie tylko za komponent, ale za fundament w ustanawianiu bezpiecznej i stabilnej podstawy dla udanych wydarzeń.

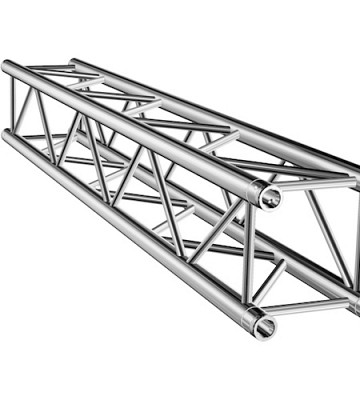

Staranna konstrukcja trussów spigot ujawnia potrzebę użycia stożkowego kołka. Nie chodzi tylko o łączenie, ale truss spigot znacznie przewyższa standardy branżowe pod względem doskonałości. Dzięki tej technice stożkowego łączenia, „truss spigot” oznacza szybkie dopasowanie i również doskonałą precyzję. Te precyzyjne połączenia gwarantują stabilne i mocne sekcje, które mogą być używane w różnych okazjach podczas organizacji szerokiej gamy wydarzeń. Tak więc, truss spigot ucieleśnia precyzję inżynieryjną, która oferuje planistom wydarzeń lub riggerom więcej niż tylko spełnienie najniższych oczekiwań dotyczących integralności strukturalnej.

Zobowiązanie do bezpieczeństwa jest niezwykle istotne w jednostce truss spigot w infrastrukturze wydarzeń, co sprawia, że jej połączenia są z natury niezawodne. W tej roli mechanizm kołka stożkowego staje się świadectwem bezpieczeństwa, zapewniając, że nie ma katastrofalnych konsekwencji wynikających z awarii strukturalnych podczas wydarzenia. To zobowiązanie jest widoczne w całym projekcie, co daje pewność osobom zaangażowanym w organizację wydarzeń i montaż. Należy zauważyć, że Spigot Truss przekształcił się w agenta bezpieczeństwa, oferując projekty, które są nie tylko innowacyjne, ale także zapewniają łatwe systemy montażu—oferując spokój umysłu, którego nie można wycenić w kategoriach pieniężnych, zwłaszcza w dynamicznym, wysokiego ryzyka środowisku biznesowym związanym z wydarzeniami.

Marka Spigot Truss znacząco zmieniła nasze postrzeganie montażu konstrukcji w dynamicznym świecie produkcji wydarzeń. To inteligentny system połączeń, który wyróżnia się spośród innych trusów spigot. Nic dziwnego, że są teraz głównymi dostawcami trusów z intuicyjnie zaprojektowanym mechanizmem stożkowego łącznika. Teraz planujący mają kolejne istotne narzędzie, które przyspiesza budowę i zapewnia solidne fundamenty. Taka niezwykła efektywność nie tylko upraszcza zadanie; sprawia, że Spigot Truss jest jedną z najbardziej niesamowitych zmian w infrastrukturze wydarzeń, takich jak te, które można znaleźć w tkance życia, między innymi.

Jeśli chodzi o jakość wykonania, nic nie mówi o tym bardziej elokwentnie niż Truss z Wtyczką dzięki swoim dobrze zaprojektowanym komponentom. Struktura jest w pełni zaprojektowana, a każda część wykonana perfekcyjnie z zastosowaniem najbardziej rygorystycznych metod i nowoczesnych procesów. Dodatkowo, to skupienie na jakości służy nie tylko celom funkcjonalnym, ale także przypomnieniem dla menedżerów wydarzeń, że kupują więcej niż tylko trusy; kupują również symbol wyróżnienia w budownictwie inżynieryjnym. Zobowiązujemy się do wprowadzenia nowych standardów jakości i wydajności na rynku produkcji rozrywkowej, który zmienia się z każdym razem.

Shenzhen Changjianshun Science and Technology Co., Ltd, strategicznie położone w Shenzhen, czołowym mieście reform i otwarcia Chin, specjalizuje się w produkcji i sprzedaży haków i sprzętu do lamp scenicznych. Nasza firma, wyposażona w dedykowany zespół badawczo-rozwojowy i sprzedaży, zatrudnia ponad 100 pracowników i działa w nowoczesnym obiekcie o powierzchni 3000 metrów kwadratowych, który obejmuje niezależne laboratorium badawcze. Po uzyskaniu certyfikatu systemu jakości IS09001 w 2011 r. i certyfikatu bezpieczeństwa TUV dla naszych hakich lamp scenicznych z Renu w Niemczech, jesteśmy niezachwiani w naszym zaangażowaniu w dostarczanie najbezpieczniejszych i najbardziej niezawodnych produktów dla każdego użytkownika

Dzięki bogatej historii 12 lat w dziedzinie haki i ośrodków, jesteśmy dumni z dostarczania produktów najwyższej jakości, wspieranych przez doskonałą obsługę i profesjonalną technologię. Nasza linia produktów wykazuje szeroką adaptacyjność, spełniając różne warunki i okazje. Nasze produkty, wykonane z najwyższej jakości metalu, są wyjątkowo odporne na korozję, zużycie i długotrwałe.

Doświadcz łatwości kompleksowych usług dostosowywania, które zapewniają jednoosobowe rozwiązanie dla wszystkich Twoich wymagań. Naszym zobowiązaniem jest dostarczanie dostosowanych doświadczeń od koncepcji do dostawy, zapewniając bezproblemową satysfakcję Twoich unikalnych potrzeb.

Proszę być pewni naszego stanowczego zaangażowania w bezpieczeństwo. Dzięki certyfikacji systemu jakości IS09001 od 2011 r. i certyfikacji bezpieczeństwa TUV dla naszych hakich lamp scenicznych z Renu w Niemczech, naszym priorytetem jest dostarczanie produktów, które przekraczają najwyższe standardy bezpieczeństwa, zapewniając niezawodność dla każdego użytkownika.

Korzystaj z naszego dwunastoletniego doświadczenia w branży haków i ośrodków. Jesteśmy dumni z dostarczania najwyższej jakości, doskonałej obsługi i profesjonalnej technologii. To zobowiązanie odzwierciedla naszą głęboką wiedzę branżową i wieloletnie doświadczenie.

Nasze produkty z haczykami i trasy są wszechstronne i nadają się do różnych wymagań w różnych środowiskach i sytuacjach. Doświadcz elastyczności naszych ofert, bezproblemowo integrując się z różnymi ustawieniami, aby zapewnić dostosowane rozwiązania dla każdego zastosowania.

Truss spigot wyróżnia się zapewnieniem stabilności strukturalnej dzięki precyzyjnym połączeniom z tapered pin. Zapewnia to solidną i bezpieczną konstrukcję, niezbędną do podtrzymywania ciężkich ładunków i rozległych ustawień wydarzeń.

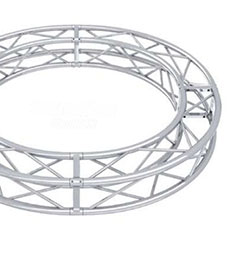

Modularny design trussu spigot pozwala na kreatywne konfiguracje, umożliwiając projektantom dostosowanie struktur do unikalnych wymagań wydarzeń. Ta wszechstronność zapewnia, że system trussu idealnie współgra z różnorodnymi wizjami kreatywnymi.

Truss spigot osiąga harmonijną równowagę, łącząc trwałe materiały z lekką konstrukcją. To nie tylko zapewnia integralność strukturalną, ale także ułatwia wygodny transport i obsługę na miejscu, odpowiadając na praktyczne potrzeby profesjonalistów zajmujących się wydarzeniami.

Truss spigot szczyci się unikalnym systemem łączenia z zwężonym pinem, co umożliwia szybki i bezpieczny montaż. Jego efektywny design minimalizuje czas montażu, co stanowi kluczową zaletę dla wydarzeń wymagających szybkiej realizacji.