Acknowledging the diversity inherent in stage setups and equipment configurations, safety cables are designed with a remarkable degree of customization in mind. Manufacturers recognize that a one-size-fits-all approach is impractical given the myriad demands of different equipment and load requirements. This adaptability ensures that safety cables seamlessly integrate into various truss systems, offering tailored solutions to accommodate the unique demands of different events. The ability to customize safety cables underscores their versatility, amplifying their significance in enhancing the safety protocols of a broad spectrum of stage productions.

Safety wires are not just parts, but representatives of security. Our dedication to industry standards is more than simply ticking a box; it is our manufacturing doctrine at its core. Making sure that our safety cables comply and often surpass the strict criteria needed in ensuring the well-being of all those involved in a live event is not only a regulatory duty but also an essential principle underlying our obligations to the industry. Our safety cables’ designs and constructions follow established standards, showing commitment for compliance with regulations while emphasizing the responsibility and hard work invested in creating these vital safety parts.

Live events are a fast-paced, rapidly evolving industry in which one-size-fits-all is not practical. This has been taken into account in the design of our safety cables that come with a remarkable customization feature. This flexibility gives us the opportunity to come up with safety cables that match different equipment and load specifications. We offer custom-made solutions that integrate smoothly into different truss systems; this way, our safety cables can be easily used in various types of occasions since they are made according to specific requirements. The varying demands of diverse events are catered for because we value customization and therefore we provide tailored solutions to address these needs through this commitment. It heightens the security procedures found in various stage presentations but also demonstrates how we respond exclusively to manifold configurations.

During this period of technological progress, safety within the entertainment sector must also develop with equal pace. Our latest innovation is our safety cables that have integrated improved technologies. By using advanced materials, unique connectors or stronger load bearing capacities, we keep on top of the innovation in the industry to ensure that our safety cables are always cutting edge. Continuously developing to meet changes in safety requirements brought about by a fast evolving live events environment, these are a great testament to our unrelenting quest for setting superior standards in terms of security through pushing the envelope and going beyond prevailing norms.

Safety cables are an indispensable part of any event setup, providing an extra layer of security to ensure the stability of lighting rigs, signage, and other suspended elements. At CJS, we offer a comprehensive range of safety cables that are rigorously tested to meet stringent safety standards, giving you peace of mind that your event infrastructure is secure and reliable.

Shenzhen Changjianshun Science and Technology Co., Ltd, strategically located in Shenzhen, the forefront city of China's reform and opening up, specializes in the production and sales of stage lamp hooks and hardware. Our company, equipped with a dedicated R&D and sales team, boasts a workforce of over 100 employees and operates from a modern facility spanning 3000 square meters, which includes an independent testing laboratory. Having achieved the IS09001 quality system certification in 2011 and TUV safety certification for our stage lamp hooks from Rhine, Germany, we are unwavering in our commitment to providing the safest and most reliable products to every user.

With a rich history of 12 years in the field of light hooks and trusses, we take pride in delivering products of first-class quality, backed by excellent service and professional technology. Our product line exhibits wide adaptability, catering to diverse environments and occasions. Crafted from high-quality metal materials, our offerings boast exceptional corrosion resistance, wear resistance, and a prolonged service life.

Experience the ease of comprehensive customization services that provide a one-stop solution for all your requirements.Our commitment is to deliver tailored experiences from concept to delivery, ensuring seamless satisfaction of your unique needs.

Rest assured with our steadfast commitment to safety. With IS09001 quality system certification since 2011 and TUV safety certification for our stage lamp hooks from Rhine, Germany, we prioritize delivering products that exceed the highest safety standards, ensuring reliability for every user.

Benefit from our extensive 12-year experience in light hooks and trusses. We take pride in delivering top-notch quality, excellent service, and professional technology. This commitment reflects our profound industry knowledge and years of valuable experience.

Our light hooks and truss products feature versatile adaptability, addressing diverse requirements in various environments and occasions.Experience the flexibility of our offerings, seamlessly integrating into different settings to provide tailored solutions for every application.

Safety cables serve as a crucial safety measure by preventing accidental falls or displacement of equipment, ensuring a secure environment during live events.

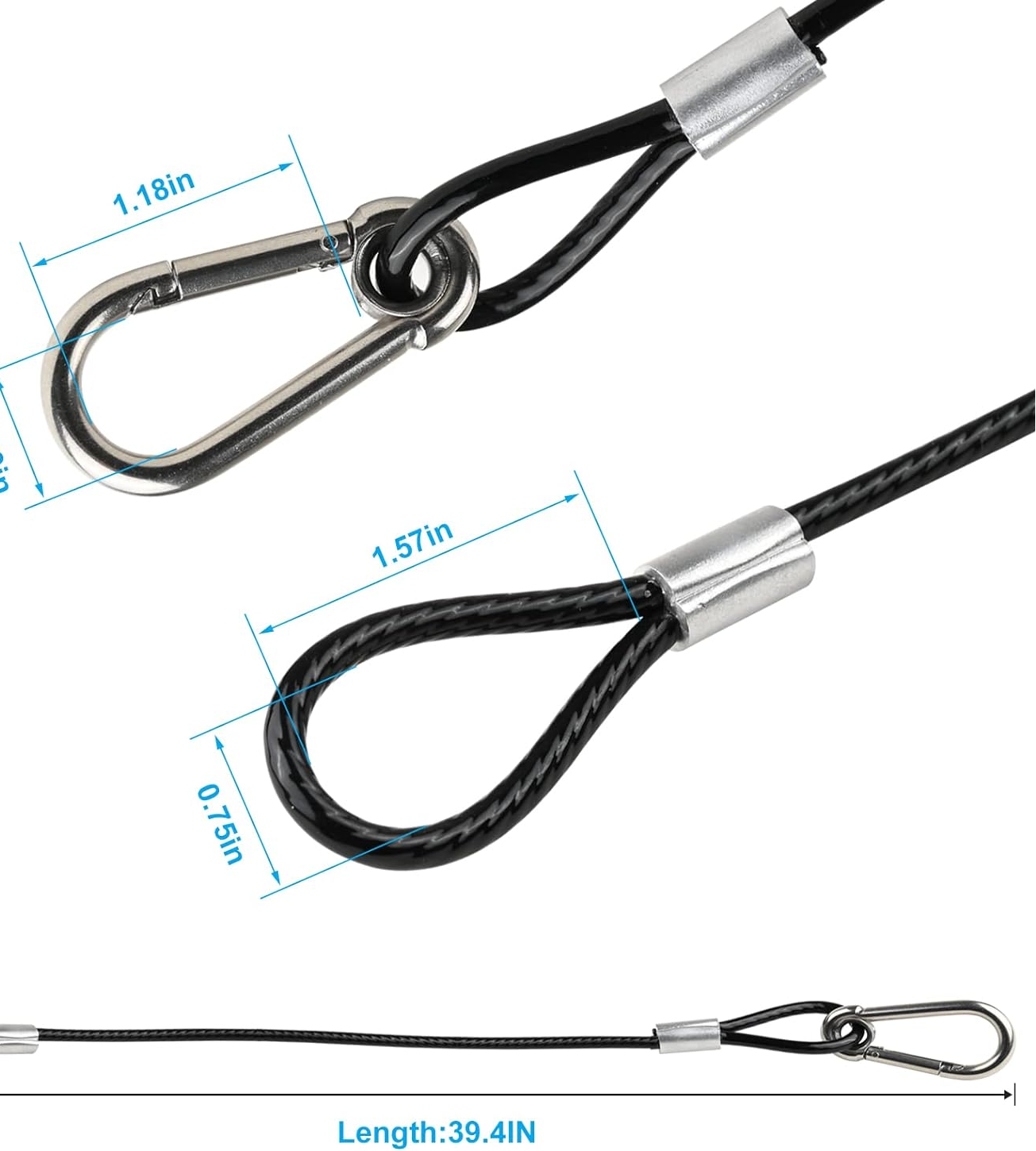

Safety cables are typically crafted from robust materials such as steel or aircraft-grade wire rope, ensuring durability and reliability in withstanding the dynamic demands of stage productions.

Yes, safety cables are often customizable to accommodate specific equipment and load-bearing needs, providing tailored solutions for diverse stage setups.

Safety cables are strategically attached to key truss components and securely connected to suspended equipment, ensuring seamless integration and enhanced safety protocols during assembly.